History

DIY Kitchens is a family run business and the UK's largest online kitchen retailer. We have been manufacturing high specification kitchens and kitchen units since 1982 and our history lies in supplying premium, high street retailers throughout the UK, however DIY Kitchens now focuses on supplying you with the same high specification kitchens, at unbelievably low prices.

1980

First kitchen produced

Our company was born in Barnsley more than 40 years ago, when our first kitchen was produced in the family home of our founders, Alf and Clare Ellis. When looking for a new kitchen, they scoured the market for a great quality kitchen at a reasonable price. With no success, they decided to make their own.

Our Managing Director Matt Ellis and his sister, Sales Director Olivia Ellis, in the home garage where our story began.

1980

Building a family business

After the first kitchen was fitted by Alf in their family home, friends and family saw it and, from their comments, Alf and Clare were encouraged to explore opening a factory and showroom – and so their family business began.

One of our first adverts featured in the Barnsley Echo newspaper.

1981

First factory

Our first showroom and factory was a 1,490 sq ft building located in Castlereagh Street, Barnsley. Here, Alf and his small team manufactured our first units and doors at the back of the retail showroom, where Clare helped customers to choose the right kitchens for their homes.

This building was originally constructed by the father of our co-founder Clare Ellis around 1940, for the world-famous manufacturer, Avery Scales.

1985

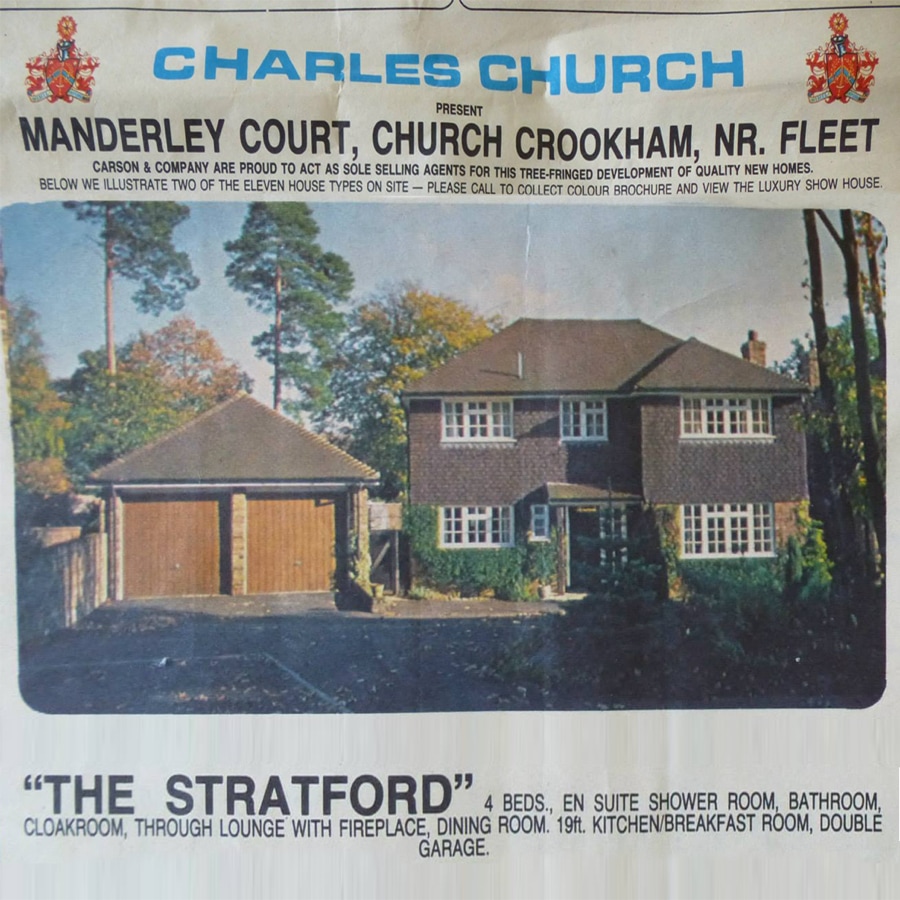

Prestigious developers

By 1985, we had moved into a 10,000 sq ft factory and, by this time, had a growing list of trade customers. Some of our early customers were local, high-quality house builders and national companies, such as Mclean Homes and Charles Church, amongst many other prestigious developers.

1985

Building on our reputation

Our new 10,000 sq ft factory also included a retail showroom, where our early team included Kitchen Designer, Linda Greenwood and our Showroom Manager, Linda Bailey. Our team had already built a loyal customer base of trade and retail customers, with whom we had a reputation for excellent quality, at the right price. 1985 was also the year that we became a limited company.

Photo shows Kitchen Designer Linda Greenwood (Top Left), Showroom Manager Linda Bailey (Bottom Right) and our company co-founder Clare Ellis (Bottom Left).

1986

Glue and dowel

1986 was the year that we produced our first glue and dowelled carcase, followed by the introduction of veneered panels and accessories - all produced in-house. Since our creation, the company has always produced kitchen cabinets with colour matched gables - a true sign of quality.

Glue and dowel construction creates a sturdier unit as there is no movement of joints by screws moving loose.

1988

Colour coordinated cabinet

By the end of 1988, we started providing our customers with 18mm, fully colour co-ordinated cabinets.

1993

Custom colours

In 1993, we began spraying kitchens to any colour that our customers requested, allowing them to create a unique kitchen of their dreams. We were also the first kitchen manufacturer in the UK to purchase a Ligmatech through-feed, automatic carcase press, with handling equipment. This investment, along with newly installed CNC drilling machines significantly increased production capacity.

Our bespoke painted option lets you choose any colour for your new kitchen.

1996

Purpose built

In 1996, we acquired the first of our two current sites near Pontefract - an industry leading, 26,000 sq ft, purpose-built manufacturing facility.

1997

Smooth painting

In 1997, we led the industry again by investing in several pieces of machinery, including a spindle moulder and CNC equipment. This allowed us to manufacture solid wood and smooth painted kitchen doors in the UK, which at the time was quite unique.

1999

Preparing for the future

1999 saw new machines working alongside our traditionally skilled craftsmen, allowing us to increase solid wood door production along with giving us the ability to manufacture our unique, foil wrapped doors.

Passing down traditional skills remains an important part of our business.

2002

Building for our future

During this period, our current Director, Matthew Ellis, joined the company. Initially, he spent time working in each manufacturing department, learning the skills required to create our kitchens, from the Falcioni spray line through to operating our beam saw and delivering customer kitchens.

Our Managing Director, Matthew Ellis, spent time learning each kitchen manufacturing skill.

2003

Taking our kitchens online

Our first move into online kitchens came in 2003 with the launch of the much-loved DIY Kitchens website. We initially started by supplying kitchen doors, handles and accessories online, direct to the public.

The original DIY Kitchens website launched in 2003.

2004

Our first online kitchen order

Our first, complete kitchen was sold online in the summer of 2004, after much consumer demand. This was the popular Eden Classic range, featuring traditional, country kitchen elements, such as beading inlay on doors and tongue and groove panelling.

The Eden Classic, our first kitchen sold online.

2007

Our unique showroom

In 2007, we built an 8,000 sq ft showroom in the grounds of our manufacturing facility near Pontefract. This helped to provide customers with the opportunity to experience the exceptional quality of our kitchens, first hand. The showroom is re-fit each year to demonstrate industry trends and innovations. During this period, we also invested over £1.3m in new equipment at our Unit 26 plant in South Kirkby, which included more efficient sawing, edging and drilling machinery, allowing us to increase production.

Our showroom is the perfect place to get a feel for the quality of our kitchens.

2009

Expanding for the future

We continued to grow and, in October 2009, we acquired a 47,000 sq ft manufacturing facility in South Kirkby, just 100m from our first site.

2010

Improving our doors

2010 saw £1m investment in hi-tech door production machinery, including a Burkle membrane press, several Biesse machines (including a saw), a CNC router and an automated storage and retrieval system.

2011

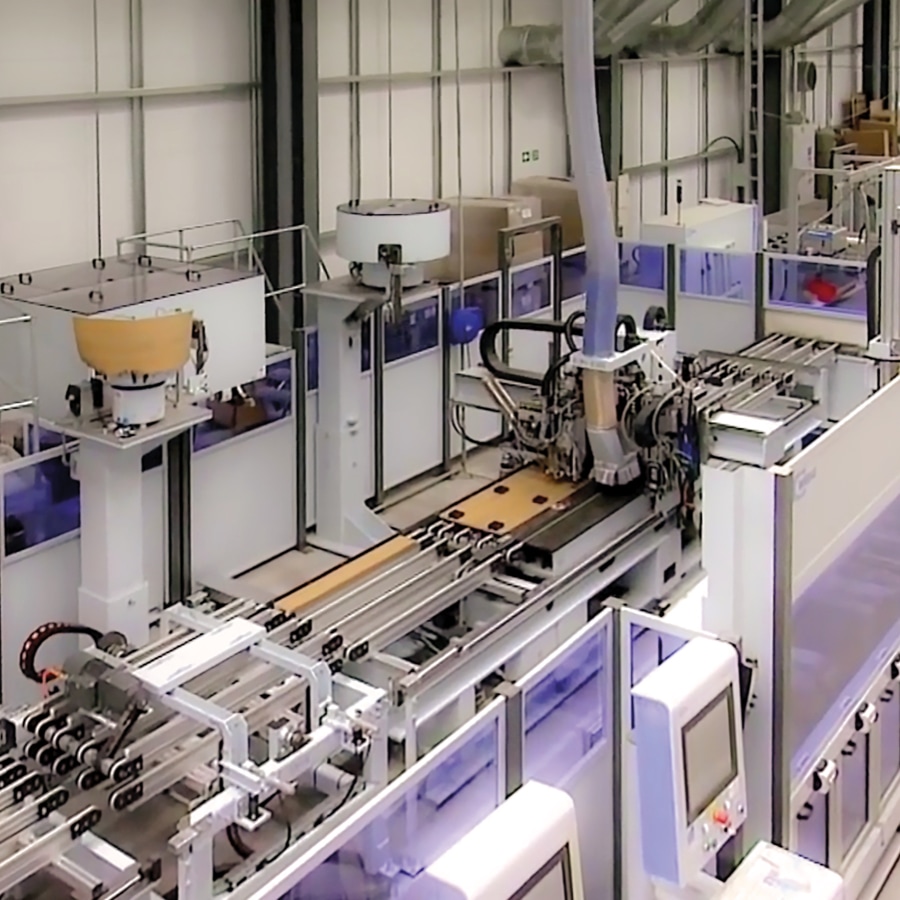

Most advanced in UK

During 2011, a 20,000 sq ft expansion to our manufacturing facilities housed a new, £1.5m automated cabinet assembly line, the most advanced in the UK and capable of producing over 100,000 cabinets each year.

2012

Investing in automation

A further £3m investment in automation in 2012 allowed us to speed up packaging and dispatch of our kitchen units.

2013

Unrivalled paint finish

In 2013, we built a 6,500 sq ft factory extension, designed to house three, new, robotic paint spraying lines. This addition not only increased our capacity but, more importantly, it also further improved the quality of our door finish.

2014

Customers love bespoke

In 2014, we installed yet another spray line to help us keep ahead of the increasing customer demand for our bespoke, painted kitchens.

2016

State of the art

We continue to lead the kitchen industry with our new, 10 acre, 152,000 sq ft manufacturing facility near Leeds, allowing us to give our customers the same choice and quality that they've come to expect, but faster than ever before. Over £12m has been invested in our ground-breaking, rigid cabinet production facility, with much of the machinery bespoke, having been designed and specified by us. The new cabinet assembly line includes 8 robots and is the longest line produced in Ligmatech Germany's history. It is capable of producing a rigid cabinet every 20 seconds and is almost 500m long - that's the length of 5 football pitches!

Designing our own bespoke machinery allows us to create better kitchens for you for less.

2017

A day to remember

In 2017, we were visited by the then UK Prime Minister, Theresa May, with the event covered by the BBC, Sky News and ITV News, amongst many other media outlets. The Prime Minister toured our manufacturing facilities, followed by a nationally televised speech and Q&A session which was enthusiastically participated in by many of our team.

UK Prime Minister, Theresa May visiting us during the 2017 General Election.

2018

Our customers first

As our business grows, we are always expanding our team to ensure product quality remains consistently high. Many of our staff have been with us since 1981. These experienced employees pass down the knowledge they have gained, ensuring continuity of skills and high standards. During 2018, we created our first purpose built Customer Support Centre to build on our hard earned national reputation and to create a team that's second to none. We also further cemented our reputation by becoming the Which? Best Kitchen Brand and by being presented with the Houzz Award for Customer Support.

Proud to be awarded Which? Best Kitchens Brand 2018 ? 2020.

2018

Just in time logistics

Further expansion of the business meant we outgrew our logistics facilities, therefore, in 2018 we opened our new, Group Logistics Centre. Coupled with large investments in a new fleet of delivery vehicles and intelligent stock systems, the new facility allowed us to continue to meet the growing demand for our kitchens.

One of our group logistics centres created to supply our business.

2019

Pushing colour forward

An additional £3.5 million into automatic paint spraying lines allowed us to double our output capacity and further increase our quality levels. With a total of 6 lines in operation, this gave us more paint spray capacity than any other kitchen manufacturer in the UK.

Since 1993, we've never stopped looking for ways to make our paint finishes more beautiful.

Get the latest offers

Register for our Newsletter and keep up to date with the latest offers, new products and kitchen trends